Read In Search of the Perfect Loaf: A Home Baker's Odyssey Online

Authors: Samuel Fromartz

In Search of the Perfect Loaf: A Home Baker's Odyssey (26 page)

Dirk Eimer, the English-speaking manager of the bakery, had told me to come at 8:30

A

.

M

., after the second shift of the day had started. The store had row upon row of wooden shelves bursting with the day’s bread, all of them dark whole grain loaves, some covered with sesame, sunflower, or caraway seeds. I approached the harried woman working the counter, but at the last minute, forgot the German phrases I had practiced. The poor woman was at a loss to understand what I wanted, especially with other customers waiting in line. So, I left and returned to the hotel, where I looked up the phrases I needed, and came back. With my remedial German, I was finally able to tell her why I was there. She immediately showed me into a floury baking room where Karl, Freddy, and Klaus, with whom I would spend the next several days, were busy shaping loaves. Eimer, who looked to be in his thirties and was the only one dressed in street clothes, walked in and said, “You’re late!” When I explained what had happened, he laughed and said, “Ah, you need to learn German.”

Indeed. One of the repeated challenges of this project was learning, observing, and absorbing lessons without the benefit of a common language. The Weichardts, for example, spoke hardly a word of English, so I was dependent on Dirk to translate for me. But, as I’ve observed before, bakers are not the most voluble or expressive characters I’ve met, nor does a spoken explanation really match the lesson you get by observing and then plunging in with your hands.

After I changed into my baker’s whites, I watched the three work quietly. The rye dough was dark and grainy, nothing like wheat flour. Freddy, a young woman just out of baking school, turned to me and said, “Here, do you want to try?” and she flung a piece of dough to me across the counter. The technique worked like this: Freddy would spread a generous amount of whole grain flour across the butcher block work surface and then pick up a piece of dough that Klaus had weighed on a scale. Using her left hand as a guide, she rolled it around with her right hand, so that it barely touched the counter. Every now and again she swept her hand through the coarse flour, so that the loaf wouldn’t stick. When the dough formed into a ball, she placed both palms on top, gave it a roll, back and forth, so that it turned into a fat log. Then she picked it up and placed it in one of the steel loaf pans on a shelf. It took maybe fifteen seconds.

Trying to mimic the movements, I picked up the dough she had thrown my way, but the shaping technique was so unfamiliar I was immediately in over my head. The loaf stuck to the counter, my hands became full of dough, and the impossibly loose, gooey, grainy mass was doing anything but forming into a neat ball.

Freddy stopped and watched me.

“What, you do not know how to do this?”

“Well, that’s why I came . . . to learn.”

She didn’t roll her eyes, but then, she didn’t have to. She just went back to work.

I sat out a few rounds as they dumped more and more dough on the counter. Karl, who was in his late fifties, worked with an economy of motion, as if he had been doing this a long time, and shaped two loaves at a time, one in each hand. He also spoke perfect English. So, while I was standing around watching, he pulled me aside and asked me to brush the bread pans with melted butter, “but not too much.” All I could think was, “This is why I flew to Berlin, to grease bread pans?” But then, I wasn’t doing anything else.

With that task done, the bakers quickly filled the pans with the rye dough, covered them with a thin sheet of plastic, left them to rise, and then went on to make more. Now Karl had me jump back into the fray, and working quite slowly, he showed me how to manipulate the dough. After several tries, I got it. The loose mass formed into a ball and I kept enough coarse flour underneath to keep it from sticking. The key was constant movement. If you stopped for a second, or if you were deliberate and considered, it wouldn’t work. The dough would stick. You had to work quickly. Plus, I had to leave behind everything I had ever learned about shaping, since it all applied to wheat dough, not rye.

Three types of rye loaves

Three types of rye loaves

The loaves I formed that day weren’t perfect, but Karl reassured me that they were okay. The dough would spread out and fill the pan as it rose, doubling in size, and all the imperfections would be gone by the time they were ready for the oven. He was right. Thirty minutes later, this incredibly fast-rising dough reached just under the brim of the bread pans and we loaded them—four pans welded together, so that they weighed twenty pounds or more—into the hot oven, dousing them with steam. They baked at a relatively high temperature of 550˚F (290˚C) for about twenty minutes, then Karl removed them with thick oven gloves and shoved them onto another level of the deck oven where it was 390˚F (200˚C), where they continued baking for another forty minutes or so. When they were dark and toasty smelling, he took them out of the ovens and dumped the loaves out of the bread pans. Then he grabbed a long steel wand off the wall and blasted the top of the loaves with hot steam, causing the crust to shine and toppings, like cumin, sunflower or sesame seeds, to better adhere to the surface. Putting on a pair of thick gloves, I helped move the loaves to a wooden drying rack.

This went on all morning until the six-foot-tall bread rack was full. There was

Roggenweizenbrot

, which was a favorite of mine and literally translates as rye-wheat-bread;

Ganzkornbrot

, a whole grain loaf with

Schrot

, or cracked rye;

Kräuterbrot

, a rye with cumin, fennel, coriander, and nettle;

Kümmelbrot

, which was plastered with caraway seeds;

Vierkornbrot

, with rye, wheat, oats, and barley; and many other loaves. One of the last ryes we made was a giant 2 kilogram (4.4 pound) Weichardt “Special,” with rye and wheat, which was hand-formed rather than risen in a loaf pan and included flour made from leftover bread. This day-old bread was cut up, dried in a low oven for an hour or more, ground up and then mixed into the dough. (Jewish bakers used a similar technique,

known as

altrus

, soaking the leftover bread in water for the next day’s dough because “nothing was wasted,” according to

Inside the Jewish Bakery

.) This adds a deeply satisfying rich taste to an incredibly dark loaf, which is why it was called the Special.

At the end of the morning, we had finished baking the pan loaves, but we were still steaming ahead. We moved on to enriched doughs made with butter that we braided into

Zöpfe

, which look similar to challah. I hadn’t done much braiding previously, so Karl taught me a three-strand braid made into a kind of cone-shaped loaf, and then a six-strand braided loaf. After a couple of days braiding dozens of loaves, the work felt automatic, as if my hands were leading me along. If I thought too much about it, though, I would inevitably screw up (which is what happened, of course, once I got home). Finally, we shaped this same dough into hundreds of

Kinderbröten

, or small rolls which the bakery gave away to children visiting the shop after school.

Despite all you hear about Europeans and their relaxed working hours, I found the pace just shy of brutal. After the first day, I started to arrive at 6:30

A

.

M

. and hit the ground running. No one in the bakery even took a lunch break, though at one point Karl sliced up a rye, showing me the under-counter refrigerator where I could find a bit of cheese or sausage. There wasn’t even a place to sit down (which made me painfully aware of how accustomed I was to sitting all day) so I just grazed while standing up. When one task was done, we moved on to another, and that went on until the day was over. No wonder most of the bakers were in their twenties or thirties. The work was grueling, especially for someone who usually baked, at most, a few loaves a day, not hundreds.

“It’s really hard,” Karl admitted. “I can’t do it every day, or if I did I wouldn’t have time for anything else.” In the evening, he played jazz bass, so he worked the last shift of the day which began at 8:30

A

.

M

. But that meant he also had the main task of cleaning up after everyone else. At fifty-seven, he was on his knees with a hand broom carefully sweeping flour out of every crack and crevice. I swept, too, with a broom, but it was clear I wasn’t getting every crumb off the floor. So later, I also got down on my hands and knees. It was kind of humbling, this sweeping and scraping of hardened bits of dough off the floor. But then, I’d said I wanted to work in a bakery. This came with the territory.

Karl, with sweeping silver hair and a warm smile, told me he grew up in Austria and never wanted to be a baker, but his stepmother pushed him to do it because that way he would always have something to eat. “Given what she’d known during the war, it seemed like the best choice,” he said. He didn’t like the work as a young man—he couldn’t go out with friends at night—but it offered a way to leave home, since bakers would give him a room, often board, too. So he apprenticed around Austria and Germany, ending up in Berlin in the 1970s, which then, as now, had a vibrant youth culture. He’d take months off from work and hitchhike through Turkey and Afghanistan, a popular path at the time, which often led to the ashrams in India. “Afghanistan was a beautiful place then,” he said wistfully. “And the hashish was very good.” He finally met up with Heinz and Mucke Weichardt a few years after they opened their bakery and has been with them ever since.

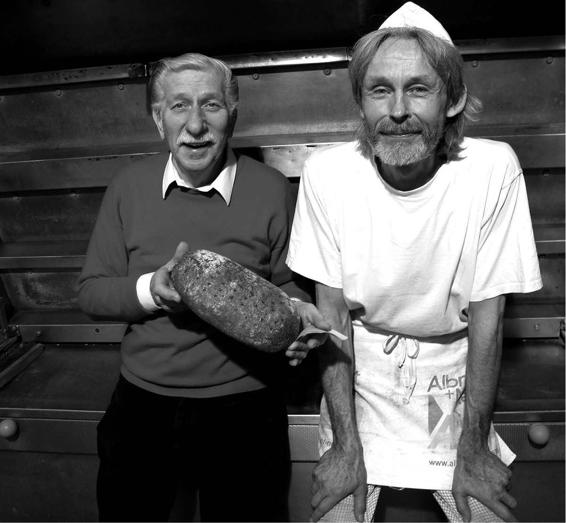

Heinz Weichardt (left) and Karl Steffelbauer in front of the oven

Heinz Weichardt (left) and Karl Steffelbauer in front of the oven

In a photo I took, Heinz and Karl are sitting in front of the oven, staring straight into the camera. “My old friend!” Karl said, when I showed him the picture. For Karl, it seemed, baking was second nature; just one part of his life.

• • •

O

ne afternoon, I stayed a bit later than usual because Karl was mixing up the Backferment for the night shift, which would arrive around midnight. They made new batches of this starter from a package of granules about once every six months, then fed the sourdough twice a day. Sekowa, the German company that makes Backferment, mixes together organic wheat, corn, chickpeas, and honey, ferments the substance, and then dries the leaven in granules and sells it in packages. It favors mild-tasting lactic acid and is quite popular among German bakers of organic breads. Home bakers can also buy it in natural food stores.