An Introduction to Rowing (3 page)

Read An Introduction to Rowing Online

Authors: HL Fourie

In a scull, each rower has two oars, one in each hand, which extend to the starboard and port side of the boat. There are the following types of sculls:

- Quad (4x). This is a shell with four seats. This is about 42 feet in length and weighs about 110 pounds.

- Double (2x). This is a shell with two rowers. This is about 34 feet in length and weighs about 58 pounds.

- Single (1x). This is a shell with a single rower. This is about 27 feet in length, a foot wide and has a weight of about 30 pounds.

Figure 9:

Quad (4x)

Figure 10:

Double (2x)

Figure 11:

Single (1x)

Boats have sliding seats that run on tracks attached to the frame of the boat. Each seat has a set of four wheels that run on a pair of tracks as shown below. The tracks are also called rails. The pair of tracks is called a slide.

Figure 12:

Seat and Slide

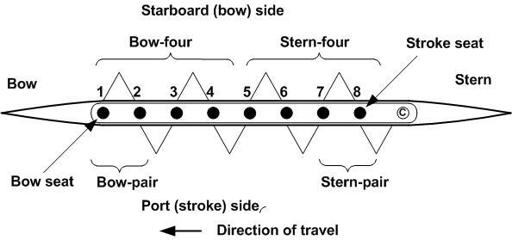

Seats are numbered sequentially from bow to stern. Number 1 seat is the bow seat and number 8 seat is the stroke seat. The port side of the boat is also called the stroke side since the stroke seat usually sits with the oar on the port side of the boat. The bow seat then has his oar on the starboard side of the boat and so this side is called the bow side.

Figure 13:

Seat Numbering

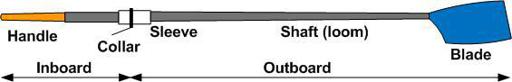

An oar, also called a blade, is made of wood or carbon fiber. The oar has the following parts: the blade (or spoon), the shaft (or loom), the collar (or button) and the handle. Today, the cleaver shaped (or hatchet) blade, invented in 1992 by Peter and Dick Dreissigacker, is widely used. The asymmetric cleaver blade has been shown to be superior to the older Macon blade (also called the spoon or tulip oar) was introduced in 1959. Prior to the Macon blade the longer square blade was used. The hatchet oar is shorter than a Macon oar since the surface of a hatchet blade is larger. Sculling oars are smaller than sweep oars.

Figure 14:

Hatchet Oar

Figure 15:

Macon Oar

Sweep boat oars are about 3.7 m (12 feet) long. Sculling oars are about 2.8 m (10 feet) long. A hatchet oar blade is about 55 cm long and 25 cm wide. The blade has a concave surface on the stern-facing side and a concave surface on the bow-facing side. The outboard length of an oar is measured from the tip of the blade to the outboard side of the collar.

The sleeve of the oar fits over the shaft where it passes through the oarlock and has a flat face to ensure that the oar blade is aligned at the right angle during the drive. The collar fits over the sleeve to prevent the oar from slipping out off the oarlock.

Figure 16:

Sleeve and Collar of an Oar

The rubber grips on the handle of a sweep boat oar are shown below.

Figure 17:

Sweep Boat Oar Handle

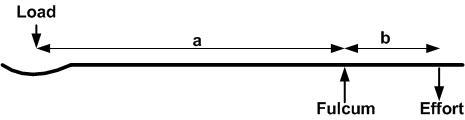

Gearing is used to adjust the load of a oar in a similar way to the gears of a bicycle. The oar can be conveniently thought of as a mechanical lever with the fulcrum at the pin of the oarlock with the load being the resistance to forward motion through the oar blade, and the effort being the force applied by the rower at the oar handle. Gearing is the ratio of the distances of the load and the effort from the fulcrum.

Gearing = a / b

Since the points at which the load and effort are actually applied are not well defined, by convention the distance a is taken as the outboard length of an oar. Distance b is the span, which for a sweep boat, is the distance between the center of the oarlock pin and the centerline of the boat.

Increasing the gearing ratio has the effect of increasing the oar load and making the boat harder to row. Typically the gearing is not usually changed once set but can be altered by moving the collar on an oar, using oars with different length, or by using a different blade design such as hatchet oars instead of Macon oars. For a sweep boat the gearing ratio is about 3.1 and is higher than that of a scull since the rowers are dealing with one oar only. The gearing of a sweep boat is given by the equation:

Gearing = outboard length / span = (overall oar length - inboard length) / span

For sculls the gearing is computed as the ratio of twice the outboard length to the span. For a scull the span is the distance between the oarlock pins. The gearing ratio of a scull is given by the equation below and usually has a value of about 2.5.