Carrier (1999) (25 page)

Authors: Tom - Nf Clancy

Once the pressure is at the desired level, there is a final check of the aircraft by the green shirts. If all appears to be at readiness, the catapult officer signals this to the pilot. The pilot selects the proper engine setting (usually maximum power or afterburner), snaps a salute back to the catapult officer in the pod, and braces for what is about to come. At that point, the catapult “shooter” hits a button in the control pod, and the twin cylinders are released. This snaps the holdback and throws the aircraft down the catapult track. The pilot/crew is hit with several times the force of gravity (what pilots call “G” forces), and their eyes are driven back into their sockets. Approximately one hundred yards/ninety meters and two seconds later, the towbar pops out of the shuttle, and the aircraft is on its own. Having achieved flying speed (usually around 150 knots), the pilot has now gained control of the airplane (that is, he or she can actually fly it).

Back on deck, a cable and pulley system retracts the shuttle to its start position, and the cycle repeats. A well-trained crew can complete this process in less than two minutes. A normal launch sequence using all four catapults can put an airplane into the air every twenty to thirty seconds. This means that launch events for several dozen aircraft can take less than fifteen minutes from start to finish. However, since the aircraft just launched will be back to land in only a couple of hours, the timing of what gets done next can be critical.

Configuring the flight deck for a landing “event” requires that the deck be “respotted,” with as many aircraft as possible moved forward. In most cases, these are parked on Rows 1 and 2, so that the “angle” will be clear for returning aircraft; and this means that Catapults 1 and 2 are now blocked and unavailable for use. While it is theoretically possible to launch aircraft during landing operations, this is rarely done. To do so would require much of the air wing to be struck below to the hangar deck, a time-consuming and tiring exercise for the deck crews. In fact, carrier captains like to use the aircraft elevators as little as possible, since these constitute part of the flight deck and parking area for aircraft when they are in the “up” position. It’s hard to find anything more precious to a carrier skipper than flight deck space, and even the four and a half acres on a

Nimitz-

class flattop seems small when filled with airplanes, ordnance, equipment, and people.

Nimitz-

class flattop seems small when filled with airplanes, ordnance, equipment, and people.

The flight deck can not only get crowded, it can easily become dangerous. For this reason aircraft that are not actually taking off or landing are parked and chained down as quickly as possible. Chaining down is also necessary because a slight list on a slick deck can send an aircraft sliding around like a rogue hockey puck on an ice rink. In fact, almost everything on deck is chained down when it is not in use, including the low-rise firefighting and aircraft tractor vehicles. Normally, as soon as an aircraft is shut down and parked, a crew of strong-backed young blue shirts moves in to attach tie-down chains to some of the thousands of tie-down points imbedded in the plating of the flight deck.

On the port side aft is a sponson holding what is called the “Lens.” This is a stabilized (against the motion of the ship) system of lights and directional lenses, designed to provide approaching pilots with a visual glide path down to the deck. If an approaching aircraft has the proper attitude and sink rate, then the pilot sees an amber light—or “meatball”—from the system. If the pilot can keep the “ball” centered (with a row of green lights) all the way down (any offset from the proper attitude shows the pilot a row of “red” lights), then it should put him down in the perfect spot for a landing on the deck aft.

Once the flight deck has been respotted for the coming landing event, and the ship has once again come into the wind, things again get exciting. Modern carrier aircraft are too heavy and their stall speeds are too high to possibly land in the roughly 500 feet/152 meters of space on the flight deck. In fact, the only way to get a high-performance airplane onto a carrier deck is to literally fly it to a “controlled” crash, and stop it forcibly before it falls into the sea. The lens system and other special landing instruments (some aircraft even have an automatic landing system) are useful aids, but pilots usually need additional help. This formidable task is the job of a lot of very special equipment and is overseen by the Landing Signals Officers (LSOs). Back in the old days of propeller-driven planes and the early jets, LSOs were the

only

landing aid for pilots. They did their job with nothing more than a pair of lighted paddles (to show the pilots their landing attitude) and a few hand signals. LSOs today do their job from a small platform on the port side aft, and it is there that we now will go to get a perspective on the fine art of a carrier landing.

only

landing aid for pilots. They did their job with nothing more than a pair of lighted paddles (to show the pilots their landing attitude) and a few hand signals. LSOs today do their job from a small platform on the port side aft, and it is there that we now will go to get a perspective on the fine art of a carrier landing.

Landing a carrier aircraft starts in the aircraft cockpit, when the pilot makes the break into the ship’s landing pattern. The pattern itself is controlled by the Carrier Air Traffic Control Center (CATCC) located one level down from the flight deck. The CATCC is a miniature of what you would find at any major airport, and it functions in exactly the same way. The controller’s job is to “stack” the aircraft, prioritize them into an oval-shaped pattern about a mile wide and four miles long around the port side of the carrier, and “stagger” them, so the LSO has the necessary time to bring each aboard. (They can land an aircraft about every thirty seconds under good conditions.) The aircraft in the pattern are prioritized by their “fuel state,” a polite way of saying that the first planes to be brought aboard are the ones that are about to fall into the ocean from fuel starvation. Just to be sure this does not happen, the carrier usually has an airborne tanker overhead during flight operations to refuel airplanes too close to the Empty point on their fuel gauges.

When the landing event has been properly organized, the “Lens” is turned on, and the first pilot in the pattern makes the “break” out of the pattern to line up on the stern of the carrier. During the “downwind” leg of the pattern, the pilot drops the plane’s landing gear, tailhook, and flaps, makes sure the radio is set up on the LSO frequency, and turns left toward the boat. Assuming all this has been done properly, the aircraft should start its final approach at eight hundred feet altitude, about three-quarters of a mile from the stern of the carrier, and just fifteen seconds from touchdown.

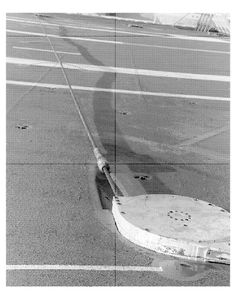

Detail of a landing wire and capstan on the USS

George Washington

(CVN-73).

George Washington

(CVN-73).

JOHN D. GRESHAM

As the aircraft finishes its break, the LSO orders the pilot over the radio to “Call the ball!” This tells the pilot to let the LSO know that he has spotted the amber “meatball” of the landing system. If the pilot does see it, he or she calls “Roger ball!” back to the LSO to confirm that. At this point, the final ten-second dash to the deck is on. On the LSO platform, the LSO and an assistant are watching and judging the aircraft’s attitude. Highly experienced pilots themselves, LSOs are expert judges of all this. In his or her hand, the LSO holds what is known as the “pickle.” This controls a series of lights near the LSO platform, which are visible to aircraft approaching the stem. As long as the aircraft continues properly on course, the pilot gets a green “OK” light. But the LSO can also activate “more power” and “wave off” lights with the “pickle.” The LSO can also coach the pilot by radio, but this is not normally done. Since an enemy could intercept radio signals in wartime conditions, “emissions control” procedures (called EMCOM Alpha in its most extreme form) dictate that combat landing operations be done only with lights. If the aircraft is set up properly, it should now be about thirty feet over the fantail, with airspeed of around 130 knots/240 kph, and a decided nose-up attitude. At this point, the pilot and LSO have done their part of the job, and it is the turn of machinery to finish it.

Handling this task is the ship’s arresting gear system, located in the middle of the 14° angle aft. Stretched across the deck are four braided steel cables (called “wires” by the crew), numbered 1 through 4, from rear to front. The wires are spaced about fifty feet apart, and each is hooked to a pair of hydraulic cylinders located one deck below. If the pilot and LSO have set the landing up properly, the aircraft should hit the deck in the roughly two-hundred-foot/sixty-one-meter-by-fifty-foot/fifteen-meter rectangle formed by the wire system. If this happens, the tailhook hanging from the rear of the aircraft should snag one of the wires. If a successful “trap” occurs, the aircraft and hook pull the wire out of its spools belowdecks, and the hydraulic cylinders slow the aircraft to a stop in about 300 feet/91.4 meters, in just two seconds. The crew is then thrown forward in their straps, and lots of negative (forward) “Gs” nearly push their eyeballs out of their sockets.

Once the aircraft is safely aboard, a green-shirted deck crew member called a “hook runner” clears the landing wire from the hook, while a “blue shirt” plane handler starts directing the pilot to taxi forward out of the landing area. When the aircraft is clear of the angle, the arresting cable is retracted and made ready for the next landing. While all this is happening, the LSO is writing down a “score” for each pilot’s landing. They grade two factors. First, the general way the pilot actually flew the approach and landing. An “OK” means that this was done safely and to accepted standards. Second, the wire the pilot “snagged.” As we saw earlier in the first chapter, the favored target is wire number 3, which provides the safest landing conditions and the least strain on the aircraft. Landings on wires 2 and 4, while acceptable, merit a lower score; but hitting wire number 1 is considered dangerous and usually brings the pilot counseling from the LSO.

Each pilot’s landing scores are posted on what is known as the “greenie” board down in the squadron ready room for all to see. These scores are accumulated, and by the end of an entire cruise, a “Top Hook” award is given to the pilot with the best landing record. The scores also frequently affect the ratings of the pilot’s airmanship, which affects their future promotion hopes. Great “Hooks” may go to test pilot school or become instructors, while those with lower scores may never fly off a ship again.

In the first chapter, I had occasion to mention one of the rules that every Naval aviator learns early: As soon as the aircraft hits the deck, push the throttles to full power. In this way, if the tailhook fails to snag a wire (called a “bolter”), he has the necessary speed to fly off the end of the angle, and get back into the landing pattern for another try. Bolters happen fairly rarely these days, though every Naval aviator still experiences them now and again. Sometimes the tailhook skips off of the deck, or just fails to connect. Whatever the reason, the 14° angled deck makes it possible for the pilot to go around again, and get aboard another time. Angled decks have saved more aircraft and aviators’ lives than any invention since the development of tailhooks. The pilot just climbs out into the traffic pattern and sets up for another try. There also is an emergency net or “barrier” that can be rigged to catch an aircraft that cannot be otherwise snagged by an arresting wire. This, however, is something that no Naval aviator cares to try out if it can be avoided.

Continuing the tour of the flight deck, you can see scattered around the perimeter of the deck many different fittings and nozzles. These provide everything from jet fuel to AFFF (Aqueous Film-Forming Foam). There is also a seawater deluge system, for nuclear/chemical washdowns and fighting

really

bad fires, as well as “chutes” where deck personnel can drop ordinance in danger of “cooking off,” should they get too hot from a deck fire. This is another of the many risks faced by flight deck personnel, though they would tell you that not doing the “dangerous” things on “the roof” is a good way to get everyone aboard killed. These are brave people, who do heroic things every time a flight evolution takes place. I defy any nation to effectively operate sea-based aircraft without such folks.

really

bad fires, as well as “chutes” where deck personnel can drop ordinance in danger of “cooking off,” should they get too hot from a deck fire. This is another of the many risks faced by flight deck personnel, though they would tell you that not doing the “dangerous” things on “the roof” is a good way to get everyone aboard killed. These are brave people, who do heroic things every time a flight evolution takes place. I defy any nation to effectively operate sea-based aircraft without such folks.

Moving on to the island, you open another hatch, head inside, and climb up six ladders to the 010 level and the Primary Flight Control, or “Pri-Fly,” as it is called. Here, some six stories above the flight deck, is the control tower for the carrier, where all the operations of the flight deck and the local airspace are handled by the Air Boss and the “Mini” Boss, his (or her) assistant. They are surrounded by computer displays showing everything they need to help them control the air action around the ship.

Climb down another ladder, and you arrive on the bridge, where the captain spends most of his time. On the port side is a comfortable elevated leather chair, which belongs to the commanding officer, and from which he normally cons the ship (flanked by computer screens). Over on the starboard side of the bridge are the actual conning stations, including the wheel, chart table, and positions for several lookouts. Even though the bridge is equipped with a GPS receiver, advanced radars, and all manner of electronic aids, human eyes and binoculars are still important to the safe conning of a carrier.

Other books

125 Physics Projects for the Evil Genius by Silver, Jerry

Sincerely, Arizona by Whitney Gracia Williams

HER CALLAHAN FAMILY MAN by TINA LEONARD

PlaybyPlay by Nadia Aidan

The Hermit by McClendon, Shayne

Cutty (Prairie Grooms Book 8) by Kit Morgan

Strawberry Wine by Phillips, Kristy

The Wedding Chapel by Rachel Hauck

A Shade of Vampire by Bella Forrest

Corporate A$$ by Sandi Lynn