Mastering the Craft of Making Sausage (12 page)

Read Mastering the Craft of Making Sausage Online

Authors: Warren R. Anderson

Tags: #Methods, #Cooking, #General, #Specific Ingredients, #Cooking (Sausages), #Sausages, #Meat

Natural casings that have been packed in salt are prepared for use by the following steps.

1. Measure the length of casing required for stuffing the batch of sausage. About 7 feet (210 cm) of small-diameter hog casing is required for 2½ lbs. (1,150 g) of sausage, and about 14 feet (420 cm) of the large-diameter sheep casing will be required. It is best to cut a little more than you think you will need; leftover casing can be returned to the container and re-salted with plain salt for future use. (Using a ruler or a tape measure to measure the length of the casing is awkward. It is better to use some kind of gauge. For example, the distance from the left side of my kitchen sink to the center of the drain is 1 foot, and I use this as a gauge to measure natural casing.)

2. Tie a short piece of string around the cut end of the casing remaining in the casing container so that the end will be easy to find next time.

3. Place the measured casing in a bowl, dishpan, or pot. Fill the container with cold water, and rinse the salt from the surface of the casing. Change the water about three times.

4. Open one end of the casing, and let water flow through the inside of the casing for a minute or so—slowly at first—until the casing has fully opened and the water is flowing through it freely. Occasionally, there will be a hole or a tear in the casing. Cut out this bad part.

5. Place the rinsed casing in a small, non-reactive container with a tight-fitting lid; add about a cup of water and refrigerate for use the next morning.

Optional:

Add 1 tablespoon of vinegar per each cup of water before refrigerating.

Note: The acid in the vinegar causes the casing to become puffy and rubber-like, and this results in a more tender cooked casing. However, most sausage makers, including myself, do not use vinegar in the water, so it would be wise to compare the two techniques. Two negative points about using vinegar are that the casing is a little more difficult to slide on the stuffing horn, and that leftover casing should be discarded because the vinegar causes profound changes in the casing.

Note:

If there is not enough time to rinse the casing the day before and refrigerate it overnight, it may be rinsed very well and soaked in lukewarm water for only 30 minutes. The casing might not be as tender and will not be as slippery, but it will be useable.

Making Sausage Patties

Generic bulk sausage that is purchased in a grocery store is usually sold in a Styrofoam tray. However, a nationally known brand of bulk breakfast sausage—such as Jimmy Dean’s breakfast sausage—is usually sold in a plastic ground-meat tube. If it is sold in a ground-meat tube, the raw sausage can be sliced into patties by cutting through the tube at approximately -inch (10 mm) intervals.

-inch (10 mm) intervals.

Similar ground meat tubes (also called

bags

) can be purchased wherever sausage casings are sold, but making patties using a mold is a cheaper and better option. A metal ground-meat mold that will make one patty at a time can be purchased, but the homemade patty mold described below is better; the homemade mold will make four patties at a time. I made the mold shown in the photographs in 1993, and I have used it countless times since then. The mold was cut from -inch (1 cm) plywood, and the diameter of each hole is 2½ inches (6.3 cm). Because it is coated with polyurethane varnish, it will withstand washing in hot, soapy water for a lifetime. In fact, it will certainly last long enough for me to pass it along to my grandchildren. It is very easy to use, and it produces patties of uniform size and thickness efficiently.

-inch (1 cm) plywood, and the diameter of each hole is 2½ inches (6.3 cm). Because it is coated with polyurethane varnish, it will withstand washing in hot, soapy water for a lifetime. In fact, it will certainly last long enough for me to pass it along to my grandchildren. It is very easy to use, and it produces patties of uniform size and thickness efficiently.

HOW TO USE A HOMEMADE SAUSAGE MOLD

1.

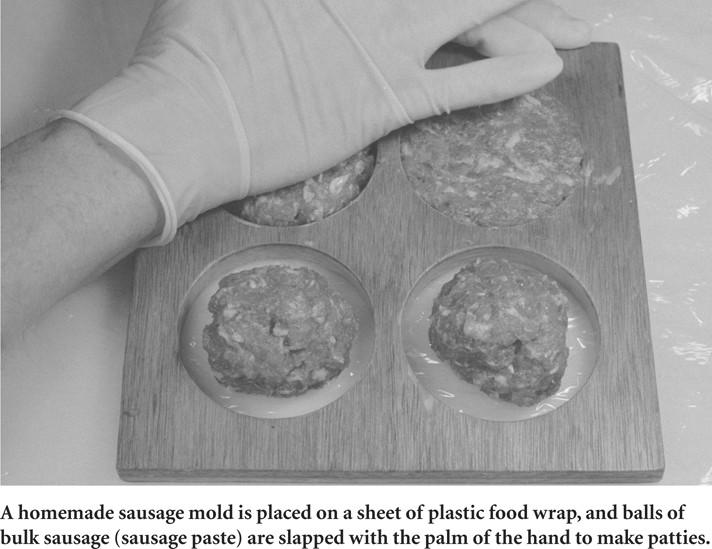

Tear off about 18 inches (45 cm) of plastic food wrap, and spread it on the counter top. Place the homemade sausage mold in the middle of the food wrap.

2.

Place an egg-sized ball of bulk sausage in the middle of each of the four mold holes.

3.

Slap the top of each ball of bulk sausage repeatedly with the palm of your hand until the sausage fills the mold. Add or remove a small amount of sausage, if necessary.

4.

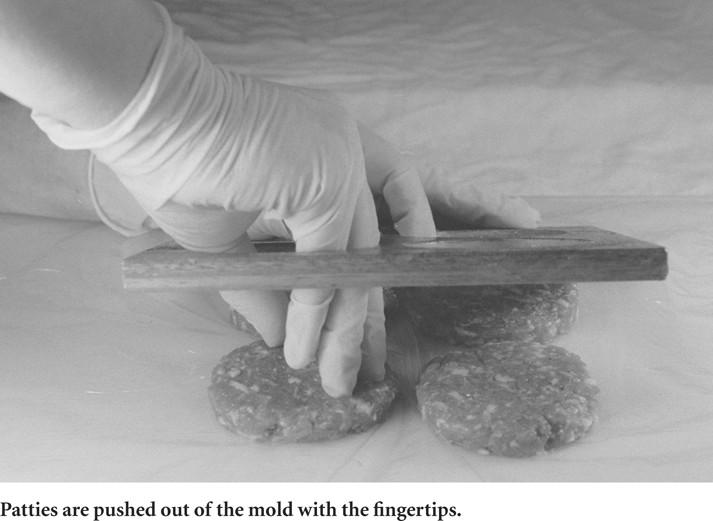

Lift one edge of the mold, and gently push the patties out of each of the mold holes. Let the patties fall back down on the food wrap.

5.

Remove the mold completely, and fold over the edges of the plastic food wrap—left, right, top, and bottom—to make an airtight package for the four patties.

6.

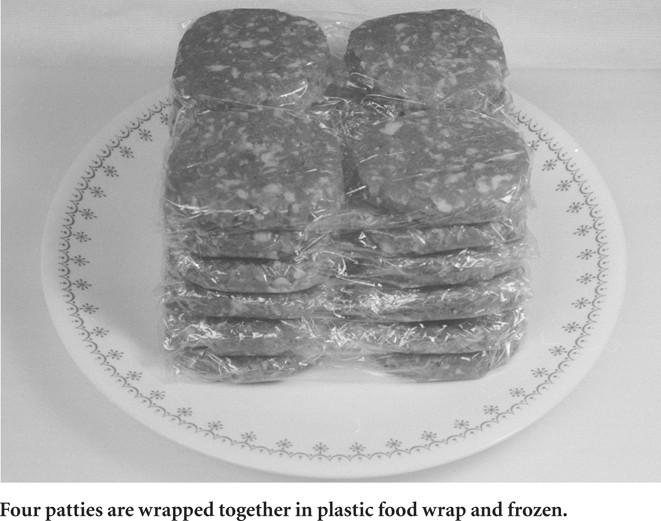

Stack the sausage packages on a dinner plate or other flat surface, and place in the freezer.

Stuffing Hog and Sheep Casings

Note: Before stuffing hog or sheep casings for the first time, it might be helpful to review the section on “Natural casings” in Chapter 3, and the section “Preparing the natural casings” in this chapter (above).

The directions below assume that you are using a cast-iron, an upright, or another similar stuffer. If you are using a stuffer attachment for a manual or electric meat grinder, two people will be required, and the tasks indicated below will have to be divided so that one person feeds the sausage paste into the grinder, and the other person does the tasks associated with stuffing the casing.

Stuffing natural sausage casing is easy to do, but there are a few pointers that should make the learning process go a little faster.

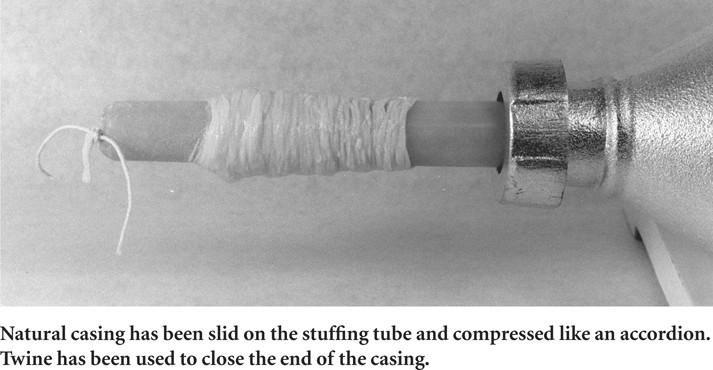

- Remove the prepared casing from the refrigerator. Rinse the casing one more time, and allow it to set in lukewarm water for about 30 minutes. The final soaking in lukewarm water makes it a little easier to slide on the stuffing tube.

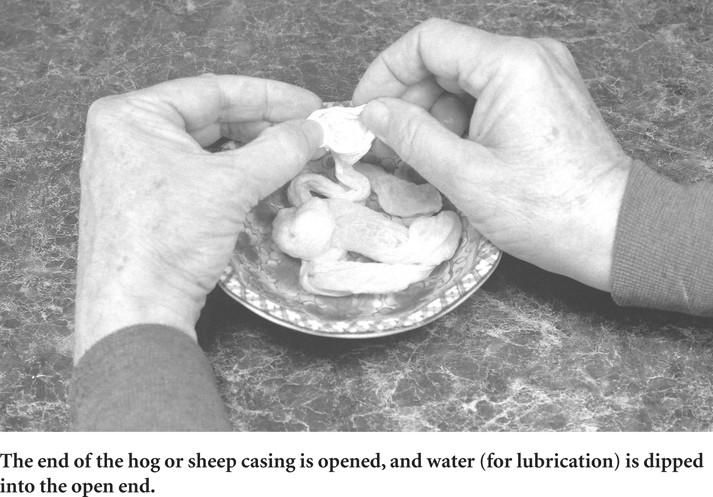

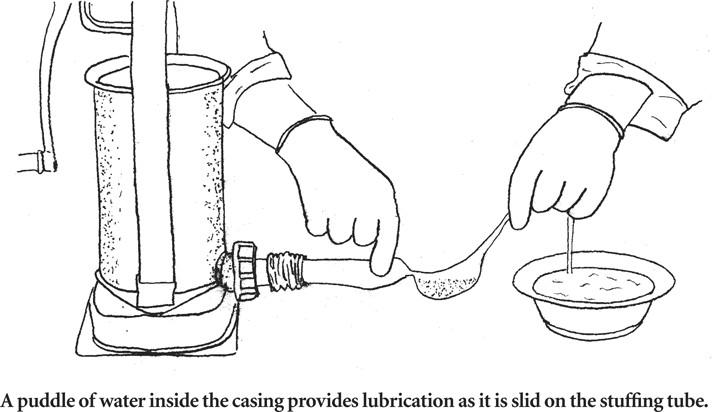

- Just before the casing is slid onto the stuffing tube, open the end of the casing, and dip the open end below the surface of the water. When this open end is raised, you will have scooped water into the casing. Do this several times so that there will be a puddle of water inside; this puddle will lubricate the casing interior as it is being slid onto the stuffing tube.

3. Attach the proper size stuffing tube to the stuffer. Use a ¾-inch (2 cm) tube for hog casings, and use a ½-inch or ⅝-inch (13 or 16 mm) tube for sheep casings. The main idea is that the casing should fit loosely on the tube, but not too loosely.