The Case for Mars (31 page)

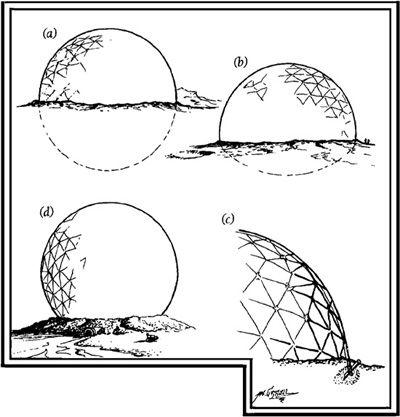

There is a way around this problem, though, one that relies on using an upper and lower hemisphere with a different radius of curvature. Place a dime on top of a quarter and you’ll see what I mean. The quarter has a larger radius and, correspondingly, a larger radius of curvature than the dime. The arc described by the bottom half of the quarter is much flatter than that described by the bottom half of the dime. So, to resolve our excavation problem, instead of using a true hemisphere for the subsurface section of the dome, we could use a partial spherical section that has a larger radius of curvature than the upper hemisphere (

Figure 7.2b

), resulting in far less excavation. For example, if the above-surface dome is a true hemisphere 50 meters in diameter (a 25-meter radius of curvature), the subsurface section could be a spherical section with a 50-meter radius of curvature. In this case, instead of having to dig a hemispherical hole 25 meters deep to house the dome, a shallow basin only 3.35 meters deep would suffice, and the total amount of soil moved would be reduced from 260,000 tonnes to about 6,500 tonnes. This latter figure makes the proposition a whole lot more practical. If digging and moving equipment capable of loading one typical dump truck (20 cubic meters) with soil every hour were employed, ne cavation job could be done in ten eight-hour shifts.

FIGURE 7.2

Methods of construction of domes on the Martian surface: (a) burying half of a spherical dome; (b) burying a dome whose lower half has twice the radius of curvature as the upper half; (c) anchoring a "tent" type dome; (d) a spherical housing complex located entirely above ground, employing Kevlar suspended decks. (Artwork by Michael Carroll)

Another alternative is to employ a hemispherical tent for the dome. With spherical domes we needed to bury the bottom half of a sphere. With a tent, all we need to do is seal the tent to the surface by burying its circular edge, or “skirt,” deep underground (

Figure 7.2

c). However, this would still require a sizable amount of excavation, as a dome 50 meters in diameter containing a pressure of 5 psi would experience a total upward force of 6,926 tonnes trying to tear it loose from the Martian surface. That’s 44 tonnes per meter of circumference. Thus, if the skirt of the dome could be anchored to a strip of ground 3 meters wide extending all the way around the dome’s circumference, and assuming once again that the dirt has a density four times that of water, then the skirt would have to be anchored 10 meters below the surface in order to have enough mass sitting on an anchor strip at the skirt’s bottom to secure the dome. To root such a dome, one way to proceed would be to dig a trench 3 meters wide, 10 meters deep, and 157 meters in circumference, bury the skirt, and then refill the trench above the dome skirt’s anchor strip. Digging this trench would require moving about 18,800 tonnes of dirt. But it’s possible that the same effect could be accomplished with a lot less work by digging a relatively narrow, shallow circular trench (say 1 meter wide by 3 meters deep—just 1,900 tonnes of digging), laying the skirt in it, and then staking the skirt into the ground with long, deep-penetrating barbed stakes. The stakes would have pipes in them through which hot steam would be sent down deep underground, where it would eventually freeze into a solid and extremely strong ring of permafrost rooting the stakes, and thus the dome, firmly in place.

A fourth alternative would be again to use a sphere, but not bury it. Instead, we could suspend decks to a series of Kevlar cables circling the sphere at various latitude parallels, as shown in

Figure 7.2

d. For example, if a 50-meter-diameter sphere were employed, the first deck could be 4 meters above the sphere’s bottom, the next at

7 meters, then 10, then 13, and so on, with decks spaced every 3 meters until the fifteenth deck, 46 meters above the surface. The total habitable area within such a structure would be enormous, about 21,000 square meters. Because of the nature of the construction, it should not be heavily loaded, so lightweight dividers made of a material such as sound-deadening plastic foam would be used to subdivide the decks into apartments, labs, cafeterias, gymnasiums, auditoriums, or whatever. Access to the structure could be via a tunnel leading to an airlock in the sphere’s “south pole.” Piling dirt around the base of the sphere would help distribute the loads created by the weight of the sphere as it weighs down on Mars. Installation of a central brick column could reinforce the load-carrying capacity of each deck and facilitate the inclusion of an elevator into the structure. Because this freestanding sphere rises so high above the Martian surface, the unpressurized geodesic Plexiglas dome required to shield it would have to be much larger than for the other concepts, but it would still weigh only about 16 tonnes.

/div>

We can see that setting up large habitable domes on the surface of Mars requires the mastery of new nontrivial civil engineering techniques in a novel environment. Thus, early Martian architecture may well resemble Roman architecture, with simple, subsurface brick vaults predominating. However, once the required manufacturing and civil engineering techniques are mastered, networks of 50-to-100-meter domes could rapidly be produced and deployed, opening up large areas of the surface to both shirtsleeve human habitation and agriculture. Within surface-rooted domes (

Figure 7.2

a,b,c), people could live in relatively conventional houses (except that they wouldn’t need roofs) made of—what else—brick. If agriculture-only areas are desired, the domes could be made much lighter, as plants do not require more than about 0.7 psi atmospheric pressure. Indeed, because of their lower pressure and reliability requirements, it is likely that Martian domes would find their first application in support of greenhouse agriculture, evolving later to enable large open-air surface settlements.

MANUFACTURING PLASTICS

As the family friend pointed out to Dustin Hoffman’

s character in

The Graduate

, the key materials in modem life are made of plastics. Get into plastics and your future is assured, my boy. Well, because Mars, like Earth, possesses abundant supplies of native carbon and hydrogen, opportunities to get into the plastics industry abound there as well.

The key to plastics manufacture on Mars is the production of synthetic ethylene, which itself can be done as an extension of the reverse water-gas shift (RWGS) reaction discussed in Chapter 6 as a means for making oxygen. You may recall the RWGS reaction:

We can use this reaction to produce all the oxygen we need on Mars by hitting Martian atmospheric carbon dioxide with hydrogen, discarding the carbon monoxide and electrolyzing the resulting water, storing the oxygen so released and then recycling the hydrogen to make more water, and thus more oxygen, and so forth. But let’s say we do things a little differently. Instead of feeding hydrogen and carbon dioxide in a ratio of 1:1 suggested by equation (1), let’s feed them together with a ratio of 3:1. Then we have:

(Yes, I know I could divide all the proportions in equation (2) in half and it would still be the same, but bear with me.) So now we take the water produced by equation (2) and condense it out. May Be we electrolyze it; may be we don’t. That all depends on whether we would rather have water or hydrogen and oxygen. The key thing, however, is what we do with the rest of the products after the water has been removed. If we choose, we can send the remaining mixture of carbon monoxide and hydrogen into another reactor, where in the presence of an iron-based catalyst they can be reacted in accordance with:

Bingo. C

2

H

4

is

ethylene

, a great fuel and the key to the petrochemical and plastics industries. Reaction (3) is strongly exothermic, and so like the methane-making Sabatier reaction discussed in Chapter

6 can be used as a heat source to provide the energy needed to drive the endothermic RWGS. It also has a high equilibrium constant, making the achievement of high ethylene yields possible. However, while more complicated, this system has important advantages over a simple Sabatier r. In the first place, ethylene has only

two

hydrogen atoms per carbon, while methane has

four. Thus, using ethylene for fuel instead of methane cuts the hydrogen importation or water-mining requirements to make fuel in half

. In the second place, ethylene has a boiling point (at one atmosphere pressure) of-104°C, much higher than methane’s boiling point of -183°C. In fact, under a few atmospheres pressure ethylene is storable without refrigeration at Mars average ambient temperatures, whereas methane’s critical temperature is below typical Mars nighttime temperatures. Therefore, ethylene can be liquefied on Mars without the use of a cryogenic refrigerator, whereas methane cannot be. This cuts the required refrigeration power for an ethylene/oxygen propellant production system about in half relative to that of a methane/oxygen production system. It also greatly reduces the need to insulate the ethylene fuel tanks, and makes handling the resulting fuel a lot simpler all around. In the third place, the density of liquid ethylene is 50 percent greater than liquid methane’s, allowing the use of smaller and therefore lighter fuel tanks on Mars ascent vehicles or ground rovers employing ethylene instead of methane fuel. Fourth, ethylene has other uses besides rocket or rover or welding fuel. It is used as an anesthetic, as a ripening agent for fruits, and as a means of reducing the dormant time of seeds. These features will all be very useful to the developing of a Mars base.

But as wonderful as all this is, it’s small potatoes compared to ethylene’s starring role as the basic feedstock for a range of processes to manufacture polyethylene, polypropylene, and numerous other plastics. These plastics can be formed into films or fabrics to create large inflatable structures (including habitation domes) as well as to manufacture clothing, bags, insulation, and tires, among other things. They can also be formed into high-density, stiff forms to produce bottles and other watertight vessels both enormous and minute, tableware, tools, implements, medical gear, and innumerable other small but necessary objects, boxes, and rigid structures of every size and descript

ion, including those that are both transparent and opaque. Lubricants, sealants, adhesives, tapes, can all be manufactured—the list is nearly endless. The development of an ethylene-based plastics manufacturing capability on Mars will thus offer enormous benefits in opening up all sorts of possibilities and capabilities necessary for the human settlement of the Red Planet.