Clive Cussler; Craig Dirgo (37 page)

Read Clive Cussler; Craig Dirgo Online

Authors: The Sea Hunters II

Tags: #General, #Social Science, #Shipwrecks, #Transportation, #Ships & Shipbuilding, #Underwater Archaeology, #History, #Archaeology, #Military, #Naval

No matter how far we hiked, no matter how deeply we penetrated the wilderness, we always found old stumps of trees that had been cut down. It seemed that everywhere we searched, the lumberjacks had gotten there first.

A fascinating piece of history tells us that when the early colonies were formed in the seventeenth century, Maine was like a prairie. Trees grew only in occasional groves. For almost two hundred years, the land was farmed. But over the decades, farmers began to give up the land for other pursuits, or they moved west. Eventually, the open lands became covered with a giant forest of trees. Today it is so thick that it is difficult to walk through.

I mentioned to Carl that it seemed the entire state of Maine had been lumbered.

He nodded, smiled, and said, “Yes, twice.”

If that is the case, why hasn’t a hunter, a troop of Boy Scouts, or an army of lumberjacks ever stumbled on the remains of an old aircraft and the bones of her pilots? Scores of rumors and accounts of people finding an old engine have floated around for years. All have proven to be dead ends. Personally, I want to hear much more than simple engine sightings. Why haven’t they also found the three huge aluminum fuel tanks that were as tall as a man, the instrument panel, the propeller that measured eighteen feet in diameter, or the dozens of other pieces that made up the aircraft?

If she hadn’t been found after three-quarters of a century, the odds were only worsening with each passing season. Groups of local people spend their Sundays searching the woods. Perhaps one day someone will get lucky and walk into the wreck before they recognize it. In the meantime, the stories still thrive of old-timers sighting odd things in the forest, of mysterious engines dragged out of the wilderness and sold for scrap, of aircraft remains on the side of mountains spotted from the air during World War II. None pans out.

Either White Bird sank out of sight in a lake, which NUMA has pretty well covered, or she crashed in the vast bog that has never been entered by man or beast.

My bet is on the bog.

Will I ever go back again?

I hate to give up. My NUMA team would have never found the

Hunley

if we had quit after the first few tries. The next step is aerial remote sensing. Even that is a long shot, but every avenue must be traveled. Someday, I’ll come back with the gang and give it another shot.

Charles Nungesser, Francois Coli, and their magnificent

White Bird

lie waiting for discovery. They merit the fame for being the first to fly the Atlantic from east to west. It would not be right to leave them in an unmarked grave in a strange land. They must be found and returned to France as heroes.

They deserve no less.

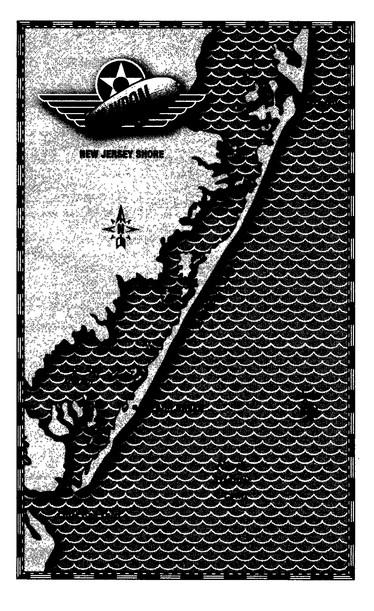

PART TWELVE

U.S.S.

Akron

I

Lighter Than Air 1931-1933

“DROP BALLAST,” COMMANDER FRANK McCORD ORDERED.

A seaman sprinted across the short space of the control room and twisted the emergency ballast lever. Within seconds, four thousand pounds of water poured into the stormy air surrounding

Akron.

The blimp rose a few hundred feet. She was now at thirteen hundred feet and holding.

The eight engines were pointed down and running full out—the ballast had been jettisoned. For a time, it seemed they had succeeded. Then the lightning, thunder, and gusts of winds enveloped them again. Within seconds, the rudder control wires were ripped loose, and the helm stopped responding.

Those on board had no way of knowing, but Akron had only minutes to live.

TWO YEARS BEFORE

“Damn,” Lieutenant (jg) “Red” Dugan said, “you could put an entire circus in this building, with room left over for a couple of Egyptian pyramids.”

Dugan was taking his first glance inside the Goodyear Zeppelin air dock in Akron, Ohio. The interior was cavernous, making the workers at the far end appear to be the size of insects. The air dock building was rounded at the top, with skylights in the sides partway up the walls to help with lighting. Huge banks of spotlights also added illumination, and at this moment they were being directed from the floor of the hangar up to the middle.

A single round duraluminum ring was suspended from the ceiling of the building. It was the first of a total of thirty-six rings that would be assembled together to form a lighter-than-air ship that would measure 785 feet in length and stand fifteen stories tall when completed. The ring consisted of inner and outer circles attached to one another by an intricate spiderweb of diamond-shaped aluminum struts. Nearest the floor and inside the inner circle were a pair of humps, where the walkways through the ship would eventually be located. The entire contraption was glowing with the dull silver color of fresh aluminum.

The Goodyear representative, Bruce Harding, was used to such reactions.

“We needed a big building to build the navy a big airship,” he said, smiling.

“What does it cost...” Dugan began to say.

“To heat it in winter?” Harding said, answering the unasked question.

“How did you know that would be my question?” Dugan asked.

“Because, Lieutenant Dugan,” Harding said, “it’s the first one everyone asks.”

“So?” Dugan said.

“A lot,” Harding said, as he directed Harding farther inside.

WHEN FINISHED, u.s.s.

Akron

would be a behemoth. The flexible skin would contain 6 million cubic feet of gas. Power would come from eight Maybach Model VL-11 engines that each produced 560 horsepower. The power plants were a twelve-cylinder V-design with a dry weight of 1,200 pounds each.

Housed in eight engine rooms, the Maybachs transferred power via sixteen-foot-long shafts to the propeller shaft. The two-bladed, sixteen-foot-diameter propellers rotated so that they were able to provide thrust in four directions.

To fuel the eight engines, Akron would carry 126,000 gallons of fuel stored in a total of 110 tanks. Extensive pipes throughout the ship would allow the aircraft commander to redistribute the fuel as it burned. This, in addition to the unique water-recovery system—a collector was mounted close to the hull above each of the eight engines—allowed the commander to keep the ship on an even keel. But that only touched on what needed to be finished.

“Everything is on schedule, Lieutenant Dugan,” Harding said. “It’s just a lot to do.”

The electrical power needed for radios, telephones, lights, winches, pumps, and fans would come from a pair of eight-kilowatt internal combustion generators. The radios were state-of-the-art, with both intermediate-frequency and high-frequency transmitters. The high-frequency transmitter gave Akron a radio range of 5,000 nautical miles. Future plans called for the addition of facsimile equipment for receiving weather maps and other data. The antenna streamed 100 feet along the hull and sometimes 800 feet deployed alongside.

Because of the 785-foot length and the many systems requiring monitoring, communication aboard the airship would be critical. A total of eighteen telephones would be installed aboard

Akron,

with each able to sound an alarm. Voice tubes, a holdover from days past, would also be used. Mechanical engine telegraphs, similar to those on other navy ships, would be used to communicate with the engine rooms.

“What about the control car?” Dugan asked.

“It will be a streamlined affair,” Harding said. “The forward third will house rudder, ballast, engine controls, and the like. The middle third is the navigation station. The last third provides access into the hull via a ladder.”

“What about a redundant control station?” Dugan asked.

“It’ll be located in the stem at the bottom of the lower control fin,” Harding said.

Dugan had studied the plans. Most of what Harding was saying was old hat.

There was to be an airplane compartment of seventy by thirty-two feet, where the five Curtiss F9C2 airplanes would be hangared. Then there were the living accommodations that would be built on each side of the aircraft compartment—a total of eight eight- by ten-foot spaces housing the crew’s toilet and washroom, bunk rooms with canvas bunks, galleys and messes for the officers, CPOs, and regular crews.

Akron

was to be a minicity, complete with airport, when finished.

“It gets cold up there in the wild blue yonder,” Dugan said.

“Aluminum piping from the forward engine rooms provides heat to the control rooms, common areas, and hangars,” Harding said, “and I’m sure the navy has some nice warm clothing for those that venture in the walkways while aloft.”

“Do you know they just changed the crew roster again?” Dugan asked.

“No,” Harding said, “what’s the latest?”

“Thirty-eight men, ten officers, and the pilots,” Dugan said.

“Over fifty men, then,” Harding said easily.

“That’s the current plan,” Dugan said.

Harding stared at the intricately woven struts that formed the single massive ring suspended from the ceiling of the hangar. “When she’s done, she’ll carry them,” Harding said, “and a whole lot more, if need be.”

ALONGSIDE THE

FRAMEWORK

of

Akron,

the Goodyear workers looked like ants on a watermelon. The workers swarmed from place to place as orders were shouted over radios and through bullhorns. The radio calls went to the operator of the overhead cranes, who carefully maneuvered the completed sections into place to be bolted to the frame. The bullhorns were used by the workers on the hull who were attaching the pieces together.

Today, the nose cone was being mounted.

The bow section was a thing of beauty: gently arcing longitudinal struts that met near the point at a small circular opening crisscrossed with aluminum support beams. It was delicate in design, sturdy in appearance, and detailed in the extreme. The crane operator dropped a hook into the center and waited while a harness was attached.

Then the crane operator raised the piece a few feet into the air to check the balance. Satisfied, the operator radioed down for the workers to attach another pair of lines starboard and port. These were attached to a second set of cranes. Once the cone was rigged, it was slowly hoisted upright, rotated sideways, and then brought alongside the main section of the hull.

Once positioned, the bow section was moved inch by inch into perfect alignment, then temporarily pinned and later bolted into place. By January of 1931, the main sections of the hull were in place and fastened down. The next few months saw the addition of the fins, elevators, and rudders. Once that was done, work began on the outer covering. The covering was sixty-five-pound-strength cotton seventy-four feet long and a foot or two wide with eyelets that were laced to the framework. This was covered with four coats of dope, two regular acetate, the last two containing aluminum powder. More than thirty thousand square yards of fabric would eventually cover the framework.

By July, the engines, propellers, water-recovery system, and other mechanical parts were being installed. On August 8, 1931, U.S.S.

Akron

was christened at a ceremony in Akron, Ohio. September 23 would be her maiden flight.

u.s.s.

AKRON,

THE latest U.S. military airship, came from a long line that stretched back to the country’s formation. President George Washington witnessed the first U.S. balloon flight in January 1793, when Frenchman Jean-Pierre Blanchard touched down from Philadelphia. Years later, the Civil War brought balloon development on both the Union and Confederate sides. Even so, it was not until the turn of the twentieth century that development truly accelerated.

In France in 1903, Albert Santos-Dumont built a successful powered dirigible, which he flew over the Parisian rooftops. A half-dozen years later, fellow Frenchman Louis Bleriot made a successful crossing of the English Channel in a powered airship capable of forty-five miles an hour. The following year, the U.S. Navy formed her first aviation group at Greenbury Point, Maryland, near Annapolis.

That first group was primarily concerned with airplanes, but there were students of lighter-than-air flight as well. By the year 1911, the British military had proved the worth of airships by successfully using them for North Sea patrol duty. That same year in Germany, Count Ferdinand von Zeppelin began the first commercial airline, with a total of five dirigibles in service.

World War I saw the first airship attack, as German lighter-than-air craft bombed London. Aviation was moving from science to practicality, and the uses continued to grow. By 1921, the U.S. Navy was compelled to form a new bureau to handle aeronautics. The bureau would be led by Admiral William A. Moffett. Almost immediately, the program suffered losses. On August 24, 1921, while undergoing trials near Hull, England, the airship that the navy had planned to purchase from England, to be designated U.S. Navy ZR-2, broke apart. Forty-three men were lost, including most of the infant U.S. Navy aeronautics program.

But the program forged on.

Using L-49, a captured German zeppelin, construction was under way on a similar 680-foot airship, to be designated

ZR -1.

She was scheduled to fly in 1923. In the meantime, only two weeks before the crash of ZR-2, the navy had taken delivery of an Italian-made semirigid airship they would name

Roma.

Quite honestly,

Roma

was a pile of trash. Her half-dozen Asaldo engines were found to be unreliable and were later replaced with U.S.-made Liberty engines. Her outer covering contained a total of 184 holes that needed patching. Once those hurdles were overcome, she took to the air. At this time, hydrogen gas was used instead of the safer helium because of cost.

Roma

made a few flights powered by the unstable gas.

On February 22,1922, however, all went wrong.

While on a flight from Langley Field to Hampton Roads, Virginia, the pilot was unable to control the unwieldy airship. Striking a telephone pole that sparked, the Italian craft burst into flames. Of the forty-five aboard, thirty-four were killed and eight injured. Remarkably, three on board exited the wreckage virtually unscathed. The incident forced the U.S. Navy to take a hard look at using hydrogen as a lifting agent and at the aeronautics program as a whole.

By 1927, when Charles Lindbergh made his historic solo flight across the Atlantic Ocean, the U.S. Navy had only a single airship in service,

Los Angeles,

which had been constructed in Germany. Around this time, the navy put out contract specifications for the construction of two large airships to supplement the fleet. The bid was won by the Goodyear-Zeppelin Corporation, based in Akron, Ohio. Two years later, in 1929, interest in lighter-than-air craft increased. The German airship

Graf Zeppelin

attempted a round-the-world flight, which was featured daily in the Hearst newspapers.

That same year, the U.S. Navy took delivery of ZMC-2, a pudgy, metal-clad zeppelin that featured eight tail fins arranged at equal intervals around the stern. From the rear, ZMC-2 had the appearance of an airplane nose cone, complete with stubby propellers. ZMC-2’s length was just under 150 feet, and she was powered by a pair of 200-horsepower Wright Whirlwind engines.

The next year, initial construction began on U.S.S.

Akron.

TUESDAY, OCTOBER 24, 1931, was a big day. Today Akron was due to be commissioned. In the huge hangar at the Rigid Airship and Experimental Squadron at Lakehurst, New Jersey, the crowd was filled with dignitaries. President Litchfield of the Goodyear-Zeppelin Corporation led the speeches.

The entire affair was broadcast on NBC affiliate WEAF for nationwide consumption. From New York City, John Phillip Sousa and his band performed a lively rendition of “Anchors Aweigh.” From Baltimore, Secretary of the Navy Charles Francis Adams made remarks, followed by Assistant Secretary of the Navy David Ingalls. From Washington, Rear Admiral William Moffett added his comments.

Back in New Jersey, the future commander of Akron, Captain Charles Rosendahl, listened to the ceremony in amusement. Rosendahl was no rookie to zeppelins. As senior surviving officer aboard the ill-fated U.S.S.

Shenandoah,

Rosendahl was known as a courageous airman. After that, Rosendahl had spent some years as skipper of

Los Angeles,

and had been a participant on

Graf Zeppelin’s

round-the-world cruise.

Rosendahl was seasoned and ready.

FIVE DAYS AFTER the ceremony, Akron made her first official flight. The passenger list included 10 officers and 49 men. This load was complemented by 31 members of the press and 19 other guests. Total passenger load was 109. Once everyone was aboard, Rosendahl began the orders to lift off.

“Engines three, four, seven, and eight,” Rosendahl said, “tilt toward ground.”