Constant Touch (14 page)

Authors: Jon Agar

Tags: #science, #engineering and technology, #telecommunications, #electronics and communications, #telephone and wireless technology, #internet, #mobile telephones

Apple launched the iPhone at the January 2007 Macworld gathering in San Francisco. Steve Jobs, at the top of his game, wowed the home audience. He began speaking at 9.15am, announcing: âWe are going to make some history together today.' For half an hour he cycled through minor achievements and developments, including the underwhelming Apple TV. Then he stepped up a gear. âThis is a day I've been looking forward to for two and a half years,' Jobs began. The audience hushed. He continued: âEvery once in a while a

revolutionary product comes along that changes everything. One is very fortunate if you get to work on just one of these in your career. Apple has been very fortunate that it's been able to introduce a few of these into the world. In 1984 we introduced the Macintosh. It didn't just change Apple, it changed the whole industry. In 2001 we introduced the first iPod, and it didn't just change the way we all listened to music, it changed the entire music industry.' With such an ancestry, the ârevolutionary product' would have to be extraordinary. But what's this? Jobs:

Well

today, we're introducing three revolutionary new products. The first one is a widescreen iPod with touch controls. The second is a revolutionary new mobile phone. And the third is a breakthrough internet communications device.

The crowd had cheered the first, redoubled their noise at the second and scratched their heads at the third.

An iPod, a phone, an internet mobile communicator. An iPod, a phone, an internet mobile communicator ... these are NOT three separate devices! And we are calling it iPhone! Today Apple is going to reinvent the phone. And here it is ...

Eventually, after a litany of complaints about the tiny keyboards and rubbish design of existing smartphones, the simple oblong iPhone appeared on the giant screen behind Jobs, looking like a grey and silver version of the alien monolith from

2001: A Space Odyssey

. The slick demo rushed through the iPhone's features â the multi-touch screen, the âpinching' of images to zoom in, the camera, the easy access to the web and to phone contacts. âYou can touch your music,' Jobs says. Indeed, touch does everything.

Several versions have followed. After the initial iPhone of 2007, which ran on old GSM standards, came 2008's iPhone 3G and 2009's incrementally improved

iPhone 3GS. The squarer and faster iPhone 4 was released in June 2010, again followed by a slightly different iPhone 4S, which included the voice-controlled personal assistant âSiri'. The taller iPhone 5 arrived in 2012. While all of these new iPhones were launched with characteristic fanfare, and were perfectly delightful products, none of them was as revolutionary as the hype suggested. Certainly, none marked the genuine qualitative leap in terms of design and consumer expectations of the original iPhone.

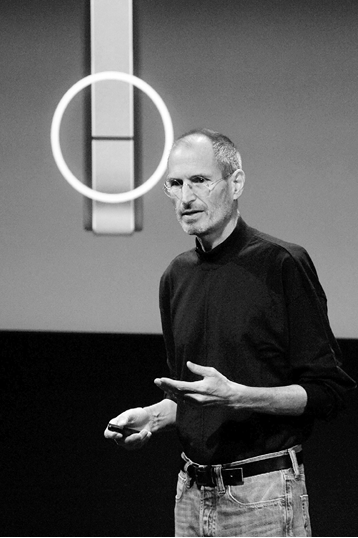

Steve Jobs at a press conference on the iPhone 4.

However

each new tweak of the iPhone served to keep the sales, which started high, extraordinarily profitable, as consumers traded in older versions for the new, fashionable device. Over a million were sold in the first year. In 2010, 40 million iPhones were sold, while the figure for 2012 was well over 100 million. The iPhone has reached all countries. In some, notably China, where China Unicom only signed a deal with Apple in 2009, unlocked iPhones were in widespread use even before they were âofficially' available. The sales were enough to push Apple beyond ExxonMobil and to become, in mid-2012, the world's most valuable company ever. From such a peak the only way is down.

Apple's rivals

Just

as there were smartphones before the iPhone, so, afterwards, Apple's rivals responded with new handsets, many of which were uncannily like the innovative Apple product. Partly this was the result of all the manufacturing companies having available to them comparable advances in technology; partly it was reverse-engineering and imitating features that may or may not be the intellectual property of others. By 2012 many touch-controlled smartphones were being made by large-scale manufacturers, and the arguments about patent infringements had reached the courts.

The most dramatic story was the entry of the Korean firm Samsung. Rather like Nokia, Samsung's origins were as a general-purpose firm, importing and exporting a range of goods, but unlike the Finnish firm it has remained a conglomerate. In the 1970s and 1980s it produced domestic electronic goods for a global market, from microwave ovens and CD players to fridges and televisions. In the 1990s it became a world leader in certain components of electronic devices, not least memory chips and liquid crystal displays. Samsung, even in South Korean terms, has been extraordinarily successful, with a corporate revenue equivalent to the GDP of a moderately wealthy country. Samsung's

mobile phones began in 1992, around the time that the second-generation, smaller, digital handsets were being introduced. Nevertheless, South Korea restricted the development of smartphones until relatively late â 2009 â which meant that any South Korean company wishing to sell them had to find ways of learning fast.

Samsung, with its range of manufacturing, could produce many, but not all, of the components needed to form a smartphone. Crucially, the South Korean firm teamed up with Google. The Californian search engine giant, headquartered a stone's throw from Apple, had developed an open operating system for mobile phones called âAndroid', based on Linux. (This was despite the fact that Google's Eric Schmidt had sat on the Apple board while the iPhone was under development. Steve Jobs was furious.) Rival operating systems, such as Windows Mobile, Symbian (the market leader, controlled by Nokia), RIM's for BlackBerry, and, of course, Apple's iOS were proprietary and closed. Google's bet was that Android's open nature would make it nimble, quicker to develop new applications for, and appealing to the broader community of coders. Google would still make money because Android users would be led to use its search engines, and the company would accumulate the profit from the ads. Samsung, on the other hand, saw a free tool, one which it did not have to pay a hefty licence fee to use, and one that would be maintained, just as Linux was, by the crowd. (Microsoft, for example,

charged between $15 and $25 per handset to use Windows Mobile in 2009. Android would cost nothing.) Many companies came together to promote Android, including other handset manufacturers such as LG (also South Korean), HTC (of Taiwan) and Motorola (of the United States). But it was the alignment of the giants, Samsung and Google, that was most significant. Note, though, that none of these immense corporations had the closed attitudes of Apple. Indeed, even while embracing Android, they continued happily to make phones using other, licensed operating systems, notably Windows Mobile. The overall point is one of contrast: the end-to-end control of Macworld's iPhone vs the shifting corporate alliances and open deals among its rivals.

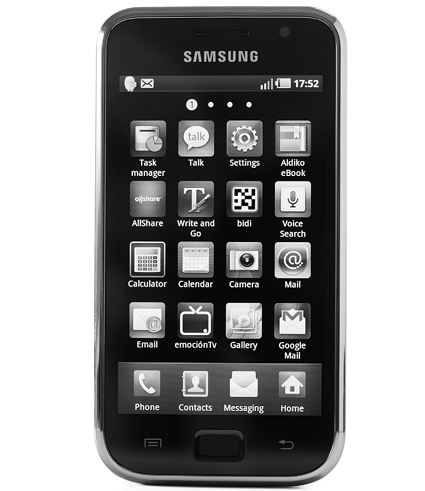

Samsung's first smartphone using the Android operating system was launched in 2009, and a small army of handsets carrying the name âSamsung Galaxy' were launched around the world in the following few years. Their diversity is an illustration of the loose-ended, diverse environment in which Samsung operates. They sold incredibly well. But the Galaxy phones had several things in common: touch screens, gesture control and apps available via an app store. Of course these were also things in common with the iPhone.

âIntellectual property' is an elastic term that covers several ways of claiming ownership of an idea. âCopyright', for example, generally covers text, and is the legal

right of an author to say that they wrote something and the âcopyright' owner alone â with a few exceptions â has the right to allow others to copy the work. I have copyright of the text in this book, and I allow Icon, the publisher, to reproduce it. A âtrademark' is a second type of intellectual property. It is a sign, usually a name or a designed logo, that tells a consumer the source of a product. On the spine of this book is a trademarked logo telling you that this book came from Icon. The third type of intellectual property is the âpatent'. Patents are

an exchange â revelation for protection â that was devised, ironically, to prevent secrecy stalling broader economic benefits: the inventor reveals details about a new inventive idea (which then becomes public knowledge) in return for a government-enforced monopoly on its exploitation for a set period of time. While this book can't be patented, almost every device or invention mentioned will have been covered by a thick layer of patents. From its origins in the 19th century, the telecommunications industry has grown up in a tangled forest of intellectual property; fiercely protected and, more often than not, just as fiercely disputed.

Samsung's Galaxy phones have fast become rivals to Apple's iPhone.

As its rivals began to eat away at Apple's smartphone dominance, so the Californian company became ever more litigious, claiming that the similar look and feel was no coincidence but was in fact due to the theft of intellectual property. Soon after Samsung launched its Galaxy phones in 2009, Apple filed a lawsuit in the United States District Court of Northern California, claiming that the South Korean firm had violated patents and trademarks, especially in fashioning the look, design, interface and even packaging of its smartphone. The lawsuits would multiply, not least because intellectual property law varies from region to region. Samsung also responded in kind. By 2011 â the first year in which Americans were buying more Android phones than iPhones â there were well over 50 lawsuits in ten countries. They covered tablet computers

as well as smartphones â not surprising, since the former were increasingly mere scaled-up versions of the latter: think of the similarities between the iPad and iPhone. In the courts, home advantage seemed to count: Samsung won most of its case in the South Korean courts, the Californian court sided with Apple in 2012, and the German and British courts fell in between. Furthermore, while Apple vs Samsung was the battle that caught the eye, there was a generalised âpatent war' involving nearly all of the big companies â Microsoft, Motorola Mobility, Google, LG, Sony, HTC, Nokia (which was forced to make Symbian open-source in response to Android), RIM and so on.

Actually, these court cases were the sites of slugfests between international corporate giants, electronics companies that depended, to a significant degree, on shared ideas and intellectual property. By one estimate, a single smartphone might be entangled in more than 250,000 active patents â not only all the patents relevant to telephony, but also those implicated in computers. What was driving the litigation was not so much outrage over the theft of ideas as competition in an increasingly crowded market by companies whose products were convergently similar.

Blood on the smartphone

As

I am writing this â in October 2012 â the number of smartphones was estimated to have topped 1 billion. (A quarter of this market is in China, with less than one in five in use in the United States.) This 21st-century market is huge and lucrative. With so much at stake, and competition so fierce, manufacturers are pressed to cut costs and drive hard bargains. And behind attractive prices lie exploitation.

Smartphones are made in a globalised, profit-driven world. The design might be made at headquarters, but the contracted manufacturer will be elsewhere, most likely in a part of the world where labour costs are low and conditions are poor. There are other crucial factors too: skills are needed, not least the engineering skills necessary to oversee the rapid and accurate production of a device. Furthermore, manufacturers need to buy in most of the components, which will come from a host of smaller suppliers. There is, therefore, a long supply chain stretching from brand owner and designer, through the principal manufacturer, to smaller companies. Each link is contractual and everyone looks for the deal that keeps costs down and profits up.

Take Apple as an example. Apple's headquarters is in Cupertino, California. The primary manufacturer for

Apple is Foxconn, a Taiwanese firm that runs factories in China. (Apple are not alone here. Foxconn, which started only in 1974, now makes two-fifths of the world's consumer electronics, including the Kindle, the Xbox 360 and the Playstation 3. It may say âAmazon', âSony' or âMicrosoft' on the outside, but Foxconn made it.) Foxconn in turn relies upon a host of smaller suppliers for components. Since 2004, the conditions in which Apple's products were made in Foxconn's Chinese factories have been repeatedly held under close media scrutiny. Allegations include long working hours, grim accommodation, the use of dangerous chemicals, aluminium dust explosions, underage employees and pressure enough to drive workers to suicide.

The

Mail on Sunday

was one of the first to draw attention to the conditions at Foxconn's factory in Shenzhen, China, in 2006. Many others have followed. Personal testimony is difficult to provide, not least because people fear for their livelihoods, but here is how one informant described Foxconn's working conditions to the

Guardian

:

Liu Jingjing, 20 (not her real name), started at Foxconn's Zhengzhou factory six months ago. The work on an iPhone production line is demanding: at first Liu found her fingers and forearms ached every day. After deductions for accommodation and food, she earns just £90 some months. Late last

year, as Christmas sales of the latest Apple phone were booming, she says overtime rose, with employees asked to work up to 100 hours a month â despite Apple's 60-hour limit.

She is one of those fortunate enough to be able to sit down on a shop floor where staff usually stand. However, she says employees are only allowed to perch on a third of the seat â to keep them ânimble'. Liu broke the rules. But because she did not sit in a standardised way she was punished by being asked to write a âconfession letter'. Recently, when she complained about a cut in overtime pay, her boss told her: âIf you do not want to work here, you can get out.'

Chinese workers on the production line at the Foxconn plant at Shenzhen, Guangdong province, 2010. (Press Association)

While

the style of manufacturing was shared by other leading companies, there are several reasons why critical media attention focussed on Apple. It was one of the richest companies in the world, making high-end products, and was not shy of portraying itself as wholesomely anti-authoritarian. There was a whiff of hypocrisy. Second, the luxury nature of the goods provided a dramatic contrast to the shoddy conditions being revealed, which made for good copy. Also, Apple was well known. This recognition meant that a debate on globalisation, which was otherwise hard to make concrete, could be brought to life. American political debates on job creation and outsourcing, particularly pertinent during a global recession, formed the context that encouraged the highlighting of Apple's woes.

Apple's first computers, including the bestselling Apple II, Macintosh and even iMac, were designed and assembled in the United States. But by 2004 manufacturing was moving abroad. Chinese factories were cheaper and more flexible. Charles Duhigg and Keith Bradsher, in the

New York Times

, give a particularly telling example. Recall that the iPhone's scratch-free âgorilla glass' was an American invention, by Corning Inc. However, cutting up the glass and assembling the pieces into iPhones was a different matter. A Chinese factory, underwritten by the Chinese government, bid for the contract and, promising immediate and flexible production, got the job. âThe entire supply chain is

in China now,' they record a former Apple executive as saying. âYou need a thousand rubber gaskets? That's the factory next door. You need a million screws? That factory is a block away. You need that screw made a little bit different? It will take three hours.' By 2011, when President Obama and Steve Jobs crossed swords on the issue, Apple employed 43,000 people in the United States, but Apple's contractors elsewhere employed 700,000. âThose jobs aren't coming back,' said Jobs.

At the beginning of this book I took an old cellphone apart, and I said that global politics could be found in its components. This is every bit as true for smartphones. However, it can be almost impossible to trace the links. Apple, in particular, makes investigation hard. In line with its closed culture of secrecy and control, it is difficult even to lift the lid off the back of the iPhone. (Walter Isaacson, in his biography of Jobs, records that âwhen Apple discovered in 2011 that third-party repair shops were opening up the iPhone 4, it replaced the tiny screws with a tamper-resistant Pentalobe screw that was impossible to open with a commercially available screwdriver'.)

But if you wrench the back off and have a look inside, what do you see? The biggest component by far is the lithium ion battery, a big fat thing oddly reminiscent â and this will only make sense if you have gutted a fish â of cod roe. There's a tiny jewel of a camera in the top corner. With the battery and some of the antenna out,

we can see the logic board, squeezed and compact. The biggest chip is the processor, made â ironically but significantly â by Samsung, Apple's rival. The central processing unit uses a design licensed from ARM Holdings, a typical British technological success story â a company that does the thinking and licensing but not the making. There are lots of smaller components: chips for GSM frequencies, an accelerometer, a flash memory (also by Samsung). Companies providing parts include Texas Instruments, Broadcom, Infineon and Skyworks Solutions.

Stripping down an iPhone is very much against company wishes. Indeed, Apple only released information identifying its contractors in January 2012 in a

step to counter criticism. Its âSupplier Responsibility Report' makes interesting but incomplete reading. We are told about the âzero-tolerance for underage labor' and the regular environmental audits. There's even a list of suppliers â 156 of them, from AAC Technologies Holdings Inc. to Zeniya Aluminium Engineering Ltd. But the report doesn't cover the conditions beyond the immediate suppliers, and we don't find out which company supplied what part and how much was paid. By one estimate, 90 per cent of the components in an iPhone were manufactured outside of the United States. Sourced from all over the world, the components are assembled to make an iPhone in China, and the final product is more likely to be bought in China than in any other country.

An iPhone 4, taken apart. Image courtesy of iFixit (www.ifixit.com).